FLOW & PRESSURE SWITCHES

• Flow Switch

• Size: 2" to 8"

• Vane type water flow switch for use in wet sprinkler systems

• Approvals: UL Listed & FM Approved

• High/Low Pressure Switch

• Designed to detect pressure increase of decrease in fire protection systems

• Explosion-proof model available

• Approvals: UL Listed & FM Approved

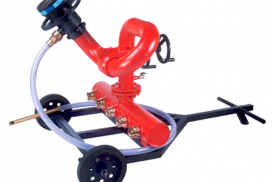

TROLLEY MOUNTED MONITOR

• Easy maneuverability

• Trolley with two solid rubber wheels

• 63 or 75 (2.5" or 3") monitors can be mounted

• Water supply manifold with 2 or 4 inlet connections of 2.5" BSP

instantaneous coupling

• Epoxy painted

TRAILER MOUNTED MONITOR

• Rugged 2 wheeled trailer with various capacities of storage tank

• Easy maneuvered by two persons or pulled behind light truck or jeep

• 80 or I 00 mm (3" or 4") monitor mounted on tank

• Over run and manual brake

• Low profile design for safety and stability

• Four stabilizer leg for added safety

• Trailer equipped with reflector

• Provision of manifold having 2.5" or 4" BSP coupling at rear side of trailer for water supply to monitor from hydrant network

• Epoxy painted

HYDRO FOAM NOZZLE- MODEL VARSHA HF60

• Factory set for single fixed flow between 4750 to

8500 lpm ( 1250 to 2245 gpm) at I 00 psi

(7.0 kg/sq.cm)

• Jet ratio controlled provider for higher flow rate

• I SO mm (6 ") flanged inlet

HYDRO FOAM NOZZLE- MODEL VARSHA HF3O

• Factory set for single fixed flow between 3030 to

47501pm (800 to 1250 gpm) at I 00 psi

(7.0 kg/sq.cm)

• 4" BSP swivel female inlet

HYDRO FOAM NOZZLE- MODEL VARSHA HF40

• Factory set for single fixed flow between 1900 to

2850 lpm (500 to 700 gpm) at I 00 psi

(7.0 kg/sq.cm)

• 3" BSP swivel female inlet

HYDRO FOAM NOZZLE- MODEL VARSHA HFJO

• Factory set for single fixed flow between I 500 to

2650 LPM (400 to 700 gpm) at I 00 psi

(7.0 kg/sq.cm)

• 2.5" BSP swivel female inlet

MASTER STREAM NOZZLE- MODEL VARSHA 60

• Factory set for fixed

flow 5680 to 2500 pm

(1500 to 3300 gpm)at 100 psi (7.0 kg/sq.cm)

•FM approved for flow up to 2200 gpm

MASTER STREAM NOZZLE- MODEL VARSHA 50

• Factory set for fixed

flow3030 to 7575 lpm

(800 to 2000 gpm)at I 00 psi (7.0 kg/sq.cm)

•4" BSP swivel female inlet base

•FM approved

MASTER STREAM NOZZLE- MODEL VARSHA 40

• Factory set for fixed flow

I 500 to 3030 pm

(400 to 800 gpm)at I 00 psi (7.0 kg/sq.cm)

•3" BSP swivel female inlet base

•FM approved

MASTER STREAM NOZZLE- MODEL VARSHA 30

• Factory set for fix flow

I 500 to 2850 lpm

(400to 750 gpm) at

I 00 psi (7.0 kg/sq.cm)

• 2.5" BSP swivel female

inlet base

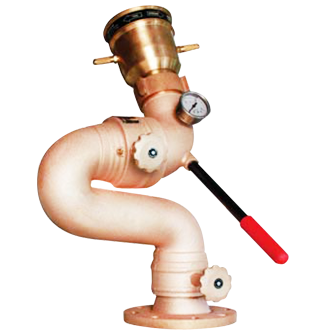

MONITOR VAJRA 331

• Cast Bronze Construction

• 360° continuous horizontal rotation

and +90° & -45° vertical elevation

or optional +85° & -0°/-15°/-30°

vertical elevation

• Liquid filled pressure gauge

• Double Row of SS ball bearing

& grease fittings

• Max operating pressure 12 kg/cm.sq

(175 psi)

• Flow up to I 000 gpm (3800 lpm)

• Vertical and horizontal movement

by handle and manual lock

MONITOR VAJRA 433

• Cast Bronze Construction

• Fully enclosed gear

• Liquid filled pressure gauge

• Double row of Stainless Steel ball bearing with grease fittings

• Maximum operating pressure

12 kg/cm.sq ( 175 psi)

• I 15 mm waterway with I 00 or

150 mm (4" or 6") flanged inlet

and 4" BSP male threaded outlet

• 360° continuous horizontal rotation,

+90°, -45° vertical elevation

• Red finish

• FM approved with VARSHA 50

nozzle for flow up 2000 gpm

(7560 lpm)

MONITOR VARUN 443 FOAM MONITOR

• Size: I 00 or 150 mm (4" or 6") flanged inlet with 4" BSP male threaded outlet

• Low profile design

• Stainless Steel waterway

• Fully enclosed worm gear for horizontal and vertical movement

• 360° continuous horizontal rotation and +90°, -65° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• Liquid filled pressure gauge

• Variable flow with nozzle model H4V (500/750/1 OOOgpm)

• Fixed flow with nozzle model H4 (500/750/1 OOOgpm)

• Red finish

• Approvals: UL Listed

MONITOR VARUN 343 BZ

• Size: 80, I 00 mm or 150 mm (3", 4" or 6") flanged inlet with 3" BSP male threaded outlet

• Low profile design

• Stainless steel 3" waterway

• Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

• Fully enclosed worm gear for horizontal and vertical movement

• 360° continuous horizontal rotation and +90°, -65° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• Liquid filled pressure gauge

• Flow up to 3030 lpm (800 gpm) friction loss less than IO psi

MONITOR MG 343 BZ

• Size: 80 mm (3") with 80. I 00 or 150 mm (3", 4" or 6") flanged inlet and 3" BSP male outlet

• Stainless steel waterway. Bronze swivel joint

• Double row of stainless steel ball bearing with grease fittings

• Liquid filled pressure gauge (optional)

• Fully enclosed worm gear for horizontal or vertical movement

• 360° continuous horizontal rotation and +90°, -45° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• Flow up to 3030 lpm (800 gpm) friction loss less than IO psi

• Red finish

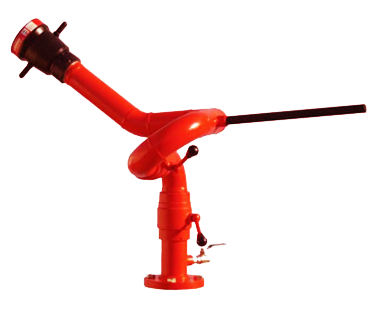

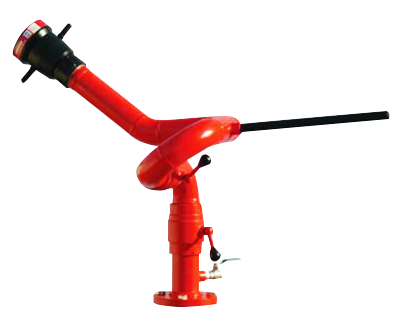

MONITOR M 341

• Size: 80 mm (3") waterway with flanged inlet of 80, I 00 or 150 mm

(3", 4" or 6") & outlet threaded to 3" BSP male

• Stainless steel construction

• Vertical and horizontal movement by handle and manual lock

• Easy deployment by one person

• Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• 360° continuous horizontal rotation & +90°, -45° vertical elevation

• FM approved with VARSHA 40 master steam nozzle having flow of 1500,

1900, 2270, 2650 & 3030 lpm (400, 500, 600, 700, 800 gpm)

MONITOR M 241

• Size: 65 mm (2.5") waterway. Inlet flanged 65. 80 or I 00 mm (2.5", 3" or 4")

and outlet threaded to 2.5" BSP male

• Stainless steel waterway

• Vertical and horizontal movement by handle and manual lock

• Bronze or Stainless steel swivel joint with double row of stainless steel ball bearing and grease fittings

• 360° continuous horizontal rotation and +90°, -45° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi).

• Flow up to 2270 lpm (600 gpm) friction loss less than IO psi

MONITOR VARUN 613

• Size: 150 mm (6") flanged inlet and outlet

• Low profile design- Hot dip galvanized Carbon steel waterway

• Bronze swivel joint with double row of stainless steel ball bearing

• Fully enclosed worm gear

• Maximum service pressure 12 kg/cm.sq ( 175 psi)

• 360° continuous horizontal rotation and +90°, -65° vertical elevation

• Liquid filled pressure gauge (optional)

• Single lifting hook

• Flow up to 12500 lpm (3300 gpm)

• FM approved with VARSHA 60 master stream Nozzle with now up to 2200 gpm

• Red finish

MONITOR VARUN 413

• Size: I 00 mm (4") waterway

• Low profile design

• Hot dip galvanized carbon steel waterway

• I 00 or 150 mm (4" or 6") flanged inlet with 4" BSP male threaded outlet

• Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

• Fully enclosed worm gear for horizontal and vertical movement of monitor

• 360° continuous horizontal rotation & +90°, -65° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• Liquid filled pressure gauge (optional)

• Flow up to 4750 lpm ( 1250 gpm) friction loss less than IO psi

• Red finish

MONITOR VARUN 313

• Size: 80, I 00 or 150 mm (3", 4" or 6") flanged inlet with 3" BSP male threaded outlet

• Low profile design

• Hot dip galvanized carbon steel 3" waterway

• Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

• Fully enclosed worm gear for horizontal and vertical movement of monitor

• 360° continuous horizontal rotation and +90°, -65° vertical elevation

• Maximum operating pressure to 12 kg/cm.sq ( 175 psi)

• Liquid filled pressure gauge (optional)

• Flow up to 3030 lpm (800 gpm) friction loss less than IO psi

• Red finish

MONITOR MG 413

• Size: I 00 mm (4") with I 00 or I 50 mm (4" or 6") flanged inlet and 4" BSP male outlet

• Hot dip galvanized Carbon steel 4" waterway and Bronze swivel joint

• Double row of Stainless Steel ball bearing with grease fittings

• Liquid filled pressure gauge (optional)

• Fully enclosed worm gear for horizontal and vertical movement

• 360° continuous horizontal rotation and +90°, -45° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• Flow up to 4750 lpm ( 1250 gpm) friction loss less than IO psi

• FM approved with VARSHA 50 master stream nozzle and solid bore nozzle NW I 000

• Red finish

MONITOR MG 313

• Size: 80, I 00 or 150 mm (3", 4" or 6") flanged inlet with 3" BSP male threaded outlet

• Hot dip galvanized carbon steel waterway and bronze swivel joint

• Double row of stainless steel ball bearing with grease fittings

• Liquid filled pressure gauge (optional)

• Fully enclosed worm gear for horizontal and vertical movement

• 360° continuous horizontal rotation and +90°, -45° vertical elevation

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• Flow up to 3030 lpm (800 gpm) friction loss less than IO psi

• Red finish

Sprinklers

CONCEALED SPRINKLER

• Standard and quick response

• Temperature rating:

• 57°C & 68°C for Sprinkler bulb & 57°C for Cover Plate

• 79°C & 93°C for Sprinkler bulb & 68°C ( I 55°F) for Cover Plate

• K-factor 5.6

• Brass Sprinkler with White or Chrome finish Cover Plate

PENDENT AND UPRIGHT SPRINKLER

• Standard and quick response with standard coverage

• Pendent or Upright mounting

• Temperature rating: 57°, 68°, 79°& 93°C

• K-factor 5.6 and 4.2

• Brass. Chrome or White/Custom colour finish

HORIZONTAL SIDEWALL SPRINKLER

•Standard and quick response with standard & extended coverage

• Horizontal Sidewall mounting

• Temperature rating: 57°, 68°, 79° & 93°C

• K-factor 5.6

• Brass, Chrome or White/Custom colour finish

SPRINKLER FLEXIBLE DROP

• Flexible Sprinkler Connections

• Complete unit, a corrugated stainless steel flexible with nipple, reducer, bar and brackets

• Sizes: 700mm, I OOOmm, I 200mm, I SOOmm, I 800mm

• Max Service Pressure - 12 kg/cm.sq

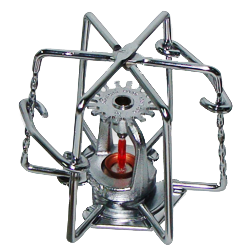

SPRINKLER GUARD

• Sprinkler guard comes in hard-wired cage design, chrome plated

• Used for encasing the sprinkler and protecting it from any inadvertent damages

• Suitable for pendent and upright mounted sprinklers

WINDOW SPRINKLER – VERTICAL SIDEWALL

• Standard and quick response with standard & extended coverage

• Vertical Sidewall mounting

• Temperature rating: 57°, 68°, 79° & 93°C

• K-factor 5.6 and 4.2

• Brass, Chrome or White/Custom colour finish

MONITOR M (ISi MARK)

• Size: 65 mm (2.5") with 1750 lpm at 7 kg/cm.sq

• Size: 80 mm (3") with 2580 lpm at 7 kg/cm.sq

• Size: I 00 mm (4") with 3500 lpm at 7 kg/cm.sq

• Hot dip galvanized carbon steel waterway

• Maximum service pressure 12 kg/cm.sq ( 175 psi)

• Monitor with fixed flow solid bore nozzle

• Bronze swivel joint with double row of stainless steel ball bearing

• Vertical & horizontal movement by handle and manual lock

• 360° continuous horizontal rotation & +90°, -45° vertical elevation

• ISi Marked

• Red finish

MONITOR M 311

• Size: 80 mm (3") waterway with flanged inlet of 80. I 00 or 150 mm

(3", 4" or 6") & outlet threaded to 3" BSP male

• Hot-dip galvanized carbon steel waterway

• Vertical and horizontal movement by handle and manual lock

• Easy deployment by one person

• Bronze swivel joint with double row of stainless steel ball bearing with grease fittings

• Maximum operating pressure 12 kg/cm.sq ( 175 psi)

• 360° continuous horizontal rotation & +90°, -45° vertical elevation

• FM approved with VARSHA 40 master steam nozzle having flow of

1500, 1900, 2270, 2650 & 3030 lpm (400, 500, 600, 700, 800 gpm)

FOAM MAKER

• Model FMA & FMA-S

• Size: 50 & 65 NB (2" & 2.5")

• Flow 75 to 550 LPM

• Carbon Steel or Stainless Steel construction

• Working pressure 2.8 to 7 kg/cm.sq

(40 to I 00 psi)

• Epoxy painted from inside and outside

• Supplied with Stainless Steel orifice

MONITOR M 211

• Size: 65 mm (2.5")

• Hot dip galvanized carbon steel waterway and Bronze swivel joint

• Double row of stainless steel ball bearing with grease fittings

• Fully enclosed worm gear for vertical movement and handle with twist lock for horizontal rotation

• 360° continuous horizontal rotation and +90°, 45° vertical elevation

• Maximum operating pressure to 12 kg/cm.sq ( 175 psi)

• Flow up to 2270 lpm (600 gpm) friction loss less than IO psi

• Red finish

Mobile Equipment

MOBILE FOAM UNIT

• 160 liters capacity in Fiber Glass Foam Tank

• I 20 to 220 liters capacity in Stainless Steel Foam Tank

• Two solid rubber wheels for easy maneuver by one person

• Mounted with bronze or stainless steel foam inductor and aluminum low expansion foam branch pipe

• Flow rate of 225/450 lpm (60/ 120 gpm) at 7 kg/cm2

• Provision of mounting two fire hoses

• Fire hoses and Foam concentrate supply (optional)

TANK COOLING NOZZLE

Descriptions

• Size: 1(2" & 3/4" BSPT or NPT

• Model: TC - Brass construction

• Model: TCS - Stainless Steel construction

• Non-automatic open orifice, fix pattern

• Used for Tank cooling applications

WATER CURTAIN NOZZLE

Descriptions

• Size: I (2" & 3/4" BSPT or NPT

• Model: WC - Brass construction

• Model: WCS - Stainless Steel construction

• Non-automatic open orifice,

fix pattern used as curtain nozzle or as window nozzle

REVERSE ACTION NOZZLE

• Size: I (2 BSPT or NPT

• Model: MV-C (without Strainer) & MV-CS (with Strainer)

• Open orifice used in deluge water spray system

• Non-automatic fixed pattern external deflector

• Solid cone discharge in the opposite direction of water inlet

• Combination of different orifices & spray angle

• K-factor (Metric): 22, 30, 35, 41, 5 I, 64, 91 & I 02

• K-factor (US): 1.54, 2.10, 2.45, 2.87, 3.57, 4.48, 5.53,

6.63 & 7.14

• Spray angle: 120° & 140°

• Finish - Brass or Nickel Chrome

JUMBO CURTAIN NOZZLE

Descriptions

• Size: 65, 80 or I 00 mm flanged end

(2.5", 3" or 4")

• Model JC Bronze construction

• Model JCS Stainless Steel construction

• Used to segregate the area by creating water curtain

• Flow I 000 to 3000 lpm (264 to

792 gpm) at 7 kg/cm.sq. ( I 00 psi)

• Produces flat water curtain projecting upwards

WATER MOTOR GONG BELL

• Model GA

• Hydraulically operated mechanical bell used along with fire protection system valves

• Corrosion resistant Aluminium alloy material, epoxy coated all over

• Wall mounted (Type B) or direct online mounting type (Type A)

• Approvals: UL Listed and FM Approved

RETARD CHAMBER

• Model RC9

• Retard Chamber is used with Alarm Valve Trim when variable pressure is anticipated in the system. It is a holding

tank to prevent sounding of Sprinkler Alarm during water pressure surge

• Material Stainless Steel

• Connection N 3/4" BSPT (F)

FOAM MAKER

• Model FCA & FCA-S

• Size: 65NB, 80NB and I OONB

• Flow from I 00 to I 800 LPM (26 to 476 GPM)

• Carbon Steel or Stainless Steel material

• Working pressure 2.8 to 7 kg/cm.sq

(40 to I 00 psi)

• Epoxy painted from inside and outside

• Stainless Steel orifice plate fitted with foam chamber

• Frangible glass vapour seal

• Solid or split deflector

RIM SEAL FOAM POURER

• Model RPA & RPA-S

• Size: 65 NB

• Rim Seal Pourer is designed to discharge foam gently as it expands and slides down inside

of the tank shell and directly in the rim seal area

• Carbon Steel or Stainless Steel

Construction

• Epoxy painted from inside and outside

WATER FOAM SPRINKLERS

• Model Fl & H

• Size: Yi" BSPT or NPT

• Air aspirating type

• Stainless Steel (FI) or Bronze (H) construction

• Working pressure 2 to 4 kg/cm.sq (30 to 60 psi)

• K - Factor 42

• Pendent mounting

• Under FM Approval